Electrospinning: An ancient nanotechnology rediscovered for modern demands

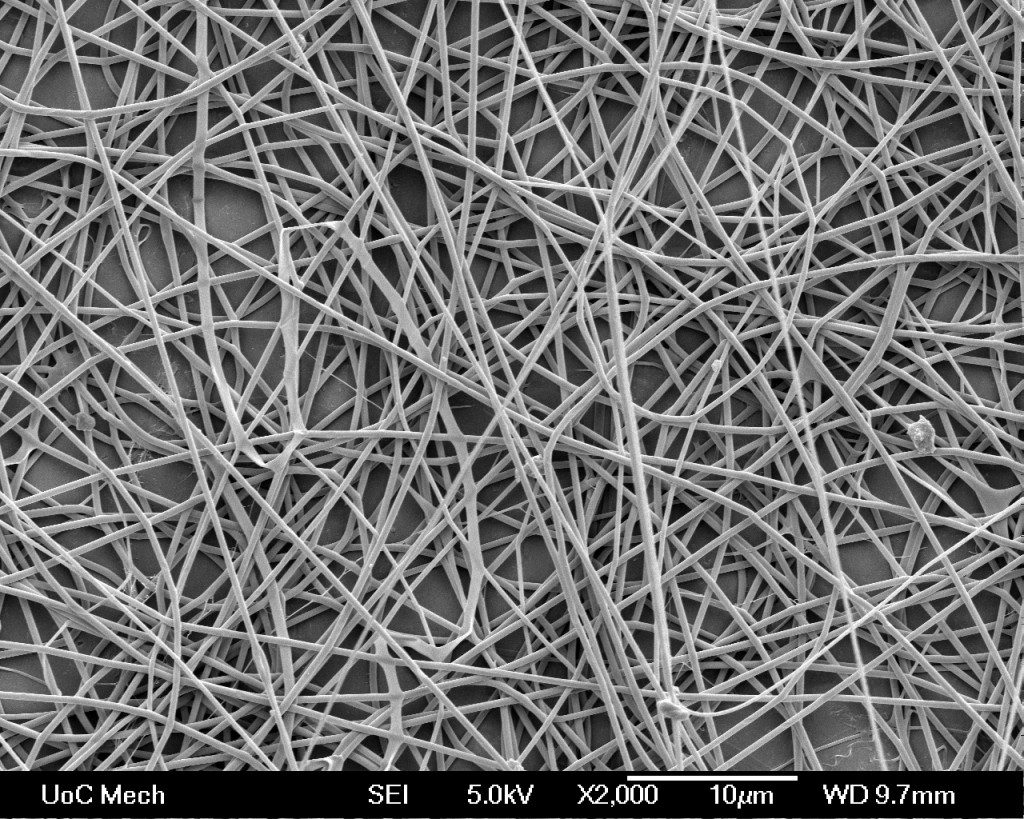

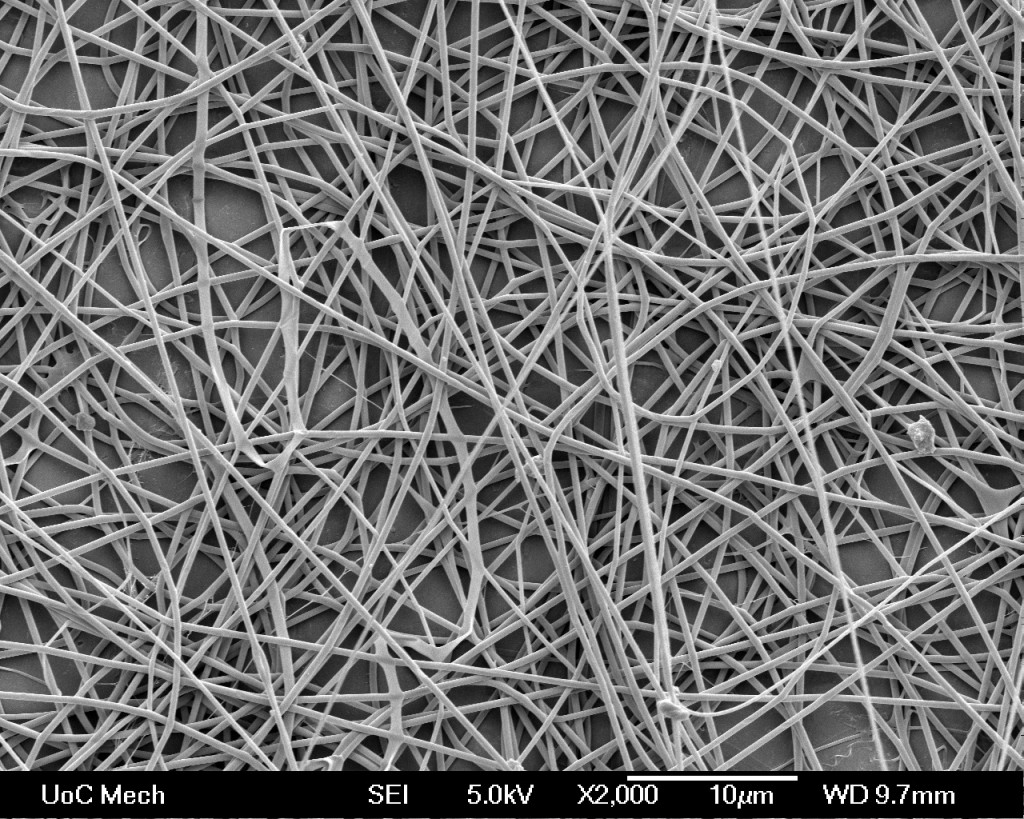

Electrosinning, the closely related cousin of electrospraying, is a method of using high voltage electric charge to draw a polymer into a fine fibre [1]. Depending on the strictness of your definition it can be considered a nanofabrication process. Electrospun fibre is commonly between 150 nm to 600 nm with extreme cases being an order of magnitude in either direction [2-3]. This places it neatly between formal nanotechnology (a single dimension less than 100 nm) and traditional microfibers (1-5 µm). The process has been known since the turn of the 20th century, not long after mass production of synthetic polymers began [4]. During the Second World War Soviet researchers developed the technology to produce high performance gas mask filters [5]. The subsequent iron curtain resulted in the technology remaining a forgotten scientific curiosity until it was rediscovered by accident in the early 90’s [6].

Figure 8 – Colour Online Only.jpg

“Photo Credit: Robert Lamberts, Plant & Food Research, New Zealand”

There are three main benefits that electrospun fibre offers [7]. From geometry, the narrow diameter of the manufactured fibre results in a very high surface area to volume ratio ideal for catalytic reactions [8] and similar processes. Due to the high degree of stretching the fibre experiences it is likely that the fibre produced will have a tensile strength that begins to approach the theoretical limit making it of great interest for nanocomposites [9]. Finally, at the nanoscale, mater sometimes obtains new properties intrinsic to its scale leading to applications in filtration and tissue engineering [10]. With emerging consumer concern over nanotoxicology, electrospun fibre has the additional benefit of being relatively unlikely to contaminate biological systems. Electrospinning usually produces one long continuous fibre. Unlike asbestos, the fibre aspect ratio is very high allowing the immune systems defences to cope efficiently with exposure without requiring safety equipment.

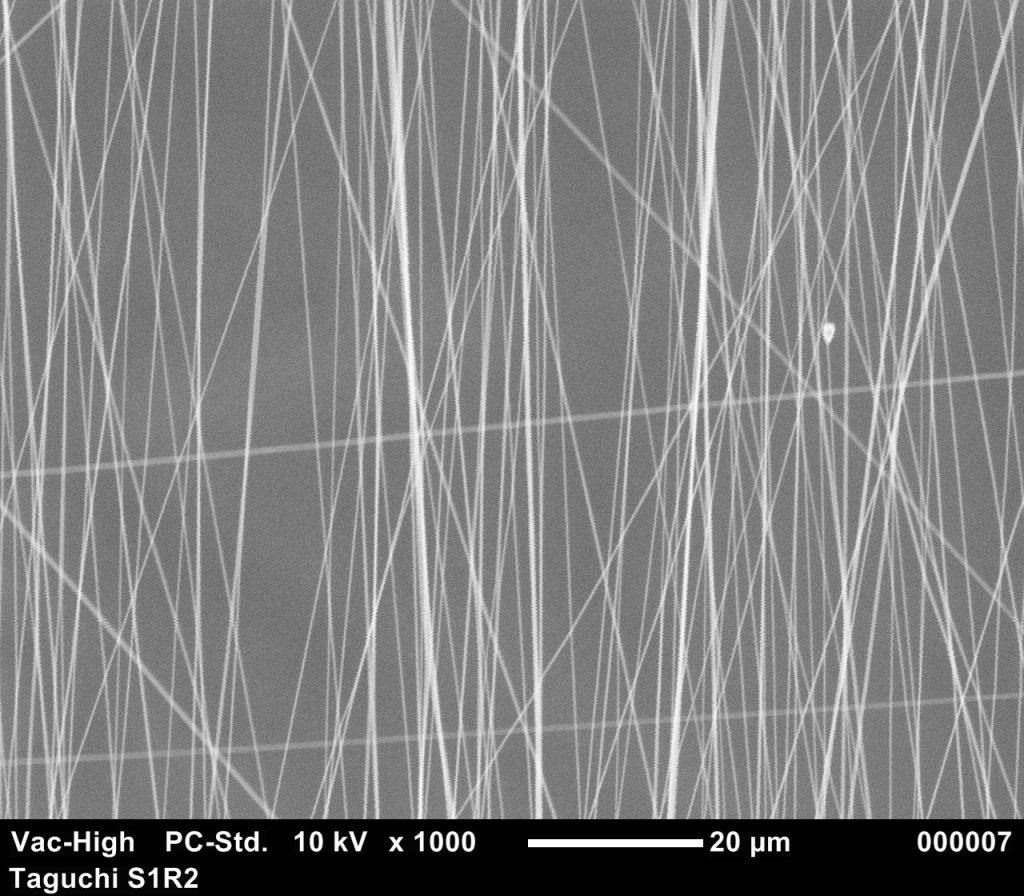

“Electrospun poly(vinyl alcohol) fibres embedded with dispersed magnetic nano iron oxide particles”

Electrospun fibre does carry some downsides. During manufacture, the fibre is ejected from a highly charged polymer droplet and pushed towards a collector by forces due to carried electric charge and high voltage static fields [11]. Part way through the process, the ejected jet becomes unstable resulting in traditional electrospinning producing random fibre coils spread over the entire deposition area. There are techniques on the market that can produce aligned fibre to varying degrees [1,5,11] however, they are almost all limited to batch processing making scale up challenging. A similar problem extends to precision placement of individual fibres which requires post-handling of the manufactured material. This limits applications in microscale electronics despite the ability to directly create insulated conductive fibres [12]. The final challenge faced by the technology since its discovery is a detailed theoretical understanding of the process itself. The current level of public knowledge often slows down commercial development due to trial and error still being required.

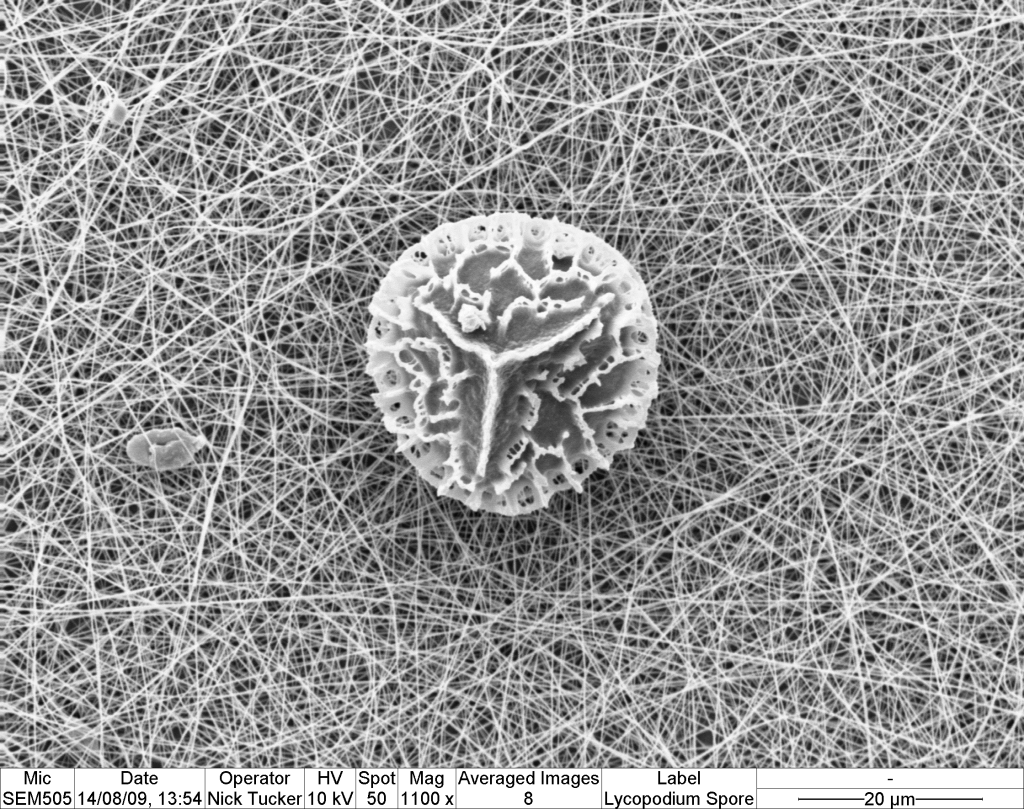

“Lycopodium fungal spore trapped on an electrospun poly(vinyl alcohol) membrane”

Electrospinning has the potential to impact many industries. With mater manipulating nanomachines still a long way from practical realization, manufacturing methods that can produce nano structured materials are the logical intermediate step. Using a two-step process it is possible to manufacture most ceramics in the form of nanofibers [13]. These fibres find their use in catalytic chemical reactions, dye sensitized solar cells and piezoelectric energy harvesting. Using conductive polymers it is possible to create conductive meshes or using co-axial technology create insulated fibres. These fibres can find use in sensors by grafting chemical sensor groups to the fibre surface. The same fibres also find use in lithium polymer batteries and high capacity capacitors [14]. The use of co-axial fibre production has also allowed the nascent development of optical waveguide fibres [15]. Rather than use co-axial fibres it is possible to directly mix mutli-component polymer fibres or electrospin multiple fibre types into a single membrane. This technology can be used to produce various energy storage devices or organic solar cells [16].

Vac-High PC-Std. 10kV x1000 (46mm)

The industrial market for electrospun fibre has experienced variable growth over its history. Early years saw growth driven by entrepreneurs such as Cooly and Morton [4] primarily aimed at the textile industry. Ultimately the technology lost against cheaper manufacturing methods. After the Soviets recognized the value of electrospun fibre for air filtration they started producing “Petryanov filters” and scaled up to 20 million m2 of filter per annum [4-5]. The infrastructure resulting from this industry lives on in one of the largest electrospinning companies Elmarco Ltd., one of the few produces of industrial scale electrospinning equipment. Much like the Soviet utilization of electrospinning, from the 1980’s onward Donaldson Inc. in the USA has been producing high performance filter materials predominantly for military applications [17]. Public information is sparse due to the intellectual property being protected as trade secrets. Other early electrospinning companies include Electrospinz Ltd. and MECC Co. Ltd. producing lab scale equipment. In the modern era there are over 30 companies around the world manufacturing products or machines.

Electrospinning is a fascinating technology with a long rich history. Steeped in potential, the technology has been tackled by a number of great minds but has yet to attract the right scientist or engineer to realize that potential. While electrospinning has seen commercial products developed in the filtration and medical markets, electrospinning has yet to see a company corner the market either in product or technology. These untapped solutions may just be the next solution key to solving a major commercial problem.

Article contributed by Dr. Jonathan Stanger

References:

[1] S. Ramakrishna, An introduction to electrospinning and nanofibers. Singapore: World Scientific, 2005.

[2] M. Costolo, J. Lennhoff, R. Pawle, E. Rietman and A. Stevens, ‘A nonlinear system model for electrospinning sub-100 nm polyacrylonitrile fibres’, Nanotechnology, vol. 19, no. 3, p. 035707, 2007.

[3] Q. Pham, U. Sharma and A. Mikos, ‘Electrospun Poly(ε-caprolactone) Microfiber and Multilayer Nanofiber/Microfiber Scaffolds: Characterization of Scaffolds and Measurement of Cellular Infiltration’, Biomacromolecules, vol. 7, no. 10, pp. 2796-2805, 2006.

[4] N. Tucker, J. Stanger, M. Staiger, H. Razzaq and K. Hofman, ‘The History of the Science and Technology of Electrospinning from 1600 to 1995’, Journal of Engineered Fibers and Fabrics, vol. 7, no. 2, pp. 63-73, 2012.

[5] Y. Filatov, A. Budyka and V. Kirichenko, Electrospinning of micro-and nanofibers. New York: Begell House, 2007.

[6] J. Doshi and D. Reneker, ‘Electrospinning process and applications of electrospun fibers’, Journal of Electrostatics, vol. 35, no. 2-3, pp. 151-160, 1995.

[7] J. Stanger, ‘Experimental Assessment of Charge Flow in Electrospinning’, Ph.D., University of Canterbury, New Zealand, 2013.

[8] S. Chuangchote, J. Jitputti, T. Sagawa and S. Yoshikawa, ‘Photocatalytic Activity for Hydrogen Evolution of Electrospun TiO 2 Nanofibers’, ACS Appl. Mater. Interfaces, vol. 1, no. 5, pp. 1140-1143, 2009.

[9] J. Kim and D. Reneker, ‘Mechanical properties of composites using ultrafine electrospun fibers’, Polymer Composites, vol. 20, no. 1, pp. 124-131, 1999.

[10] K. Hofman, N. Tucker, J. Stanger, M. Staiger, S. Marshall and B. Hall, ‘Effects of the molecular format of collagen on characteristics of electrospun fibres’, J Mater Sci, vol. 47, no. 3, pp. 1148-1155, 2011.

[11] A. Andrady, Science and technology of polymer nanofibers. Hoboken, N.J.: Wiley, 2008.

[12]A. Luzio, E. Canesi, C. Bertarelli and M. Caironi, ‘Electrospun Polymer Fibers for Electronic Applications’, Materials, vol. 7, no. 2, pp. 906-947, 2014.

[13] V. Tomer, R. Teye-Mensah, J. Tokash, N. Stojilovic, W. Kataphinan, E. Evans, G. Chase, R. Ramsier, D. Smith and D. Reneker, ‘Selective emitters for thermophotovoltaics: erbia-modified electrospun titania nanofibers’, Solar Energy Materials and Solar Cells, vol. 85, no. 4, pp. 477-488, 2005.

[14] L. Wang, Q. Xiao, Z. Li, G. Lei, L. Wu, P. Zhang and J. Mao, ‘Synthesis of Li2CoTi3O8 fibers and their application to lithium-ion batteries’, Electrochimica Acta, vol. 77, pp. 77-82, 2012.

[15] G. Kwak, G. Lee, S. Shim and K. Yoon, ‘Fabrication of Light-Guiding Core/Sheath Fibers by Coaxial Electrospinning’, Macromol. Rapid Commun., vol. 29, no. 10, pp. 815-820, 2008.

[16] S. Chuangchote and T. Sagawa, ‘Application of Electrospun Nanofibers in Organic Photovoltaics’, Nanostructure Science and Technology, pp. 141-162, 2014.

[17] S. Cavaliere, Electrospinning for advanced energy and environmental applications. CRC Press, 2015.

Tags:fibrestech review