Today we bring you an exciting inside view of what it is like to be an engineer on oil and gas rigs. We interview Loai Khalayli an active IEEE member who provides us with detailed information about his life and how he ended up working in this exciting industry.

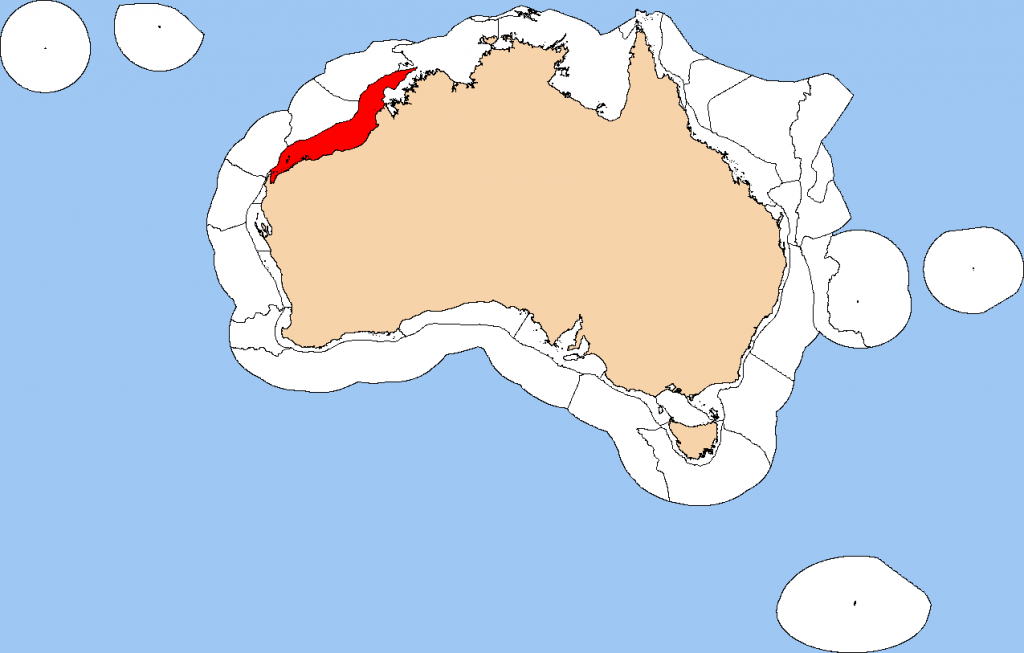

Woodside Petroleum gas find off Australia’s west coast. Image courtesy: Couriermail

1. Loai Please tell us a little about yourself?

I was born in a little town called Al Ain, in the United Arab Emirates. Having spent the majority of my life (22 years) in the UAE, I completed all my schooling, and my bachelor degree in Electrical & Electronics Engineering at the American University of Sharjah (AUS). After that, I decided to cross the Indian ocean and went to Melbourne University for a master degree in Mechatronics Engineering.

2. What prompted you to move to Australia?

Australia is a beautiful country: its nature, people, lifestyle, standard of living, culture (or multi-culture) are unique. When I got my offer to study in Melbourne, at Australia’s top university, I couldn’t reject it, and decided it was time to move to another part of the world.

Loai receives award – HH Sheikh Hamdan Bin Rashed Al Maktoum in Dubai

3. Please tell us about your involvement with the IEEE?

Without exaggeration, the IEEE has shaped my life. It all started when I was a freshman student exploring student clubs at a club fair at AUS. I joined the “sub-committee” as a volunteer for the IEEE student branch. It wasn’t long before I realized that I had joined one of the most important technical organizations in the world. We were organising international conferences, technical workshops with major companies, social events, and lots of other great events. The hard work immediately paid off with the networking opportunities and the lifelong friends I made from companies and universities around the world. It was one thing that brought us altogether – our passion for IEEE.

Two semesters after my join date, I was offered the opportunity to join the team for a partially sponsored study tour to France. That was a one-of-a-kind experience: a highlight of that trip was a visit to the Airbus manufacturing facility in Toulouse, at which we saw the A380 being assembled. The most impressive aspect of the study tour was that it was completely organized by students for students.

Loai, the rig and nothing but ocean as far as the eye can see

Over the next years, I held different positions in the committees of IEEE student branches at AUS and University of Melbourne. Over the course of 6 years volunteering for the IEEE, I was exposed to many different projects which developed my professionalism. It provided me with a wide spectrum of skills: technical (from conferences, publications, etc.), and organizational/leadership/social skills (from our committee projects). Most importantly, it exposed me to difficult situations, and taught me how to deal with people, as well manage my time as I juggled volunteering around my studies and part-time work.

Another notable experience I’ve had with the IEEE is when my undergraduate senior project won the second prize in the IEEE Myron Zucker Student Design Competition. As a result, my team and I were flown to Las Vegas, Nevada to present our project at the IEEE Industry Application Society AGM. People from all around the world were present to showcase their work.

4. You were recently employed by Woodside Petroleum. Please tell us about your journey of employment.

I started working with Woodside in February 2015 (not long ago!). So far, it has been a very rewarding journey. Working in this sector requires a very strong focus on safety – a requirement for all employees travelling to offshore platforms is the completion of the TBOSIET, which stands for Tropical (water) Basic Offshore Safety Induction and Emergency Training. This entails fire-fighting, escaping a smoke-filled room (with zero visibility), escaping an upside down submerged helicopter, survival at sea, first-aid and lots of other aspects. It can be a bit daunting at first, but then once the safety culture is built into your mind, you can never think differently – the first thing you would do at arrival to any place (even if it’s a cinema, or a hotel) is identify emergency exits and map your escape routes.

Another part of the job that I have enjoyed learning is specialised knowledge in hazardous areas (all our electrical devices must be explosion-proof). Woodside provides its graduates many opportunities to learn on-the-job, while allowing graduates to be creative in solving the toughest problems! It has been very challenging to learn about hazardous areas, while being presented with non-conventional problems. I feel like I’m breaking new boundaries every single day.

5. Woodside is the largest operator of Oil & Gas in Australia. Tell us about some of the major projects you have been involved in?

Currently, I’m working on the North West Shelf Project, Australia’s largest resource development project. Specifically, I am working on the offshore gas processing platforms. These platforms are some of the largest in the world in size and gas processing capacity. Visiting the sites is not an ordinary visit – many of our projects have held or hold world records.

Northwest Shelf – Australia

Being part of the frontline engineering team that keeps the plant up and running is a very interesting experience. The plant runs 24 hours a day, 7 days a week, 365 days a year, and if a fault occurs, it needs immediately attention. Being called into the office on a weekend/public holiday/weeknight is not unexpected (of course, employees follow fatigue management plans that allow them to take a day off in certain cases)!

6. You travel a lot as part of your work and spend time in remote sites including oil/gas rigs. What is it like to work on a rig? Can you describe what a typical day will consist of?

I do get to travel to sites in the North West of Australia, off the coast of the town of Karratha. It takes about 5 to 6 hours to get there from Perth (Capital of the Western Australian state) between a fixed wing flight, a helicopter ride, and airport waiting times. Once you arrive there, you are briefed with safety instructions, and are allowed to start work afterwards.

A working day on-site is about 12 hours, with regular scheduled breaks for re-energizing. The day starts early, with a 6 am start, and goes ahead with the morning meeting: this covers information on the different work on site, the weather conditions, and the plan for the day. All those are talked about with relevance to safety: how can all the work be done such that everyone can return home safely. After that, everyone heads off to their job, which can be very different from one person to another. On some days, I find people calibrating sensors, and on others I see turbines being dismantled.

Loai undertaking his duties on the rig during a typical day

I guess the most interesting part about working offshore is the people you meet – great characters, and lots of technical experience. More importantly, the safety culture that people live and breathe is quite impressive. People look after each other all the time. Another very important learning curve is the Permit-to-Work system: this system essentially prevents conflicting works (in terms of safety, or for functionality of the plant) from happening at the same time. There are several other aspects covered by this system, such as electrical isolations, process isolations, etc. depending on the work being undertaken.

7. What advice can you offer to other Young Professional members looking to get into this sector of work?

I strongly recommend any engineer who is considering joining this industry to explore it – it’s a world of its own, and it holds great learning opportunities. The work is never monotonous – one day you’re in the office meeting engineers, the next day you’re testing equipment in a lab. Other days you find yourself on a helicopter on your way to site. One thing I’d like to stress on is joining a company that looks after the safety of its employees. The reality is it’s a hazardous industry, and having many people working on the same plant requires a lot of management, planning, and knowledge of the plant structure for everyone to be safe. One thing that I’m proud to say is that Woodside has great safety accomplishments.

8. Anything else you want to add?

Yes. I’d just like to mention one thought that always came to my mind. Every transition stage of one’s life is like hitting a ‘reset’ button, or perhaps, a step applied to one’s system – whether it’s a new city you move to, a new job/industry, a new degree/university, etc. Change is something that one always has to embrace to be successful. People can handle change differently – but it may be a good idea to take changes in small steps – this ensures that you are always stable (excuse my control systems terminology!). Nevertheless, my advice to everyone is to move outside of their comfort zones, reach the unreachable, and work their way smartly to success!

Interview and editing – Dr. Eddie Custovic, Editor-in-Chief, IEEE IMPACT